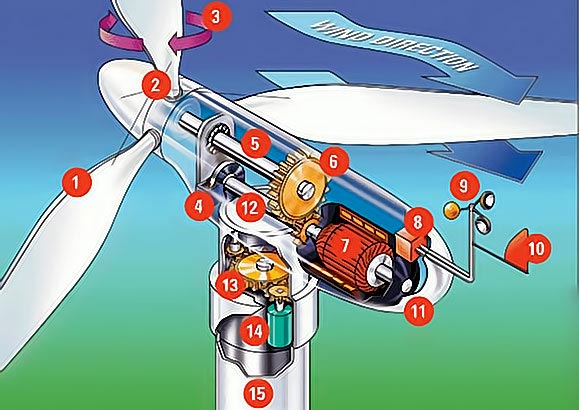

Wind Turbine Components

A wind turbine has the following components:

Wind Direction: Pictured in our diagram is an "upwind" turbine, so-named because it operates facing into the wind. Other turbines can be designed to face away from the wind and are called "downwind".

1. Blades: Most turbines have either two or three blades. Wind blowing over the blades causes the blades to "lift" and rotate. Blades come in various sizes and have tended to grow over the years. In the early 1980s, a typical blade was likely to be 33 feet (10 meters) long, and such a wind turbine could generate about 45 megawatt-hours per year. By 1990 the typical blade measured 89 feet (27 meters) and could produce 550 kilowatt-hours per year. In the early twenty-first century blades as long as 233 feet (71 meters) can generate 5,600 megawatt-hours per year.

2. Rotor:The rotor is the hub around which the blades are connected. Often, however, ''rotor'' is used to refer to the hub and the blades as a single unit. The rotor is the key component, because it translates the wind's kinetic energy into torque (TORK), or turning power.

3. Pitch: Blades are turned, or pitched, out of the wind to control the rotor speed and keep the rotor from turning in winds that are too high or too low to produce electricity.

4. Brake: A disc brake, which can be applied mechanically, electrically, or hydraulically to stop the rotor in emergencies.

5. Low-speed shaft: The rotor turns the low-speed shaft at about 30 to 60 rotations per minute.

6. Gear box: Gears connect the low-speed shaft to the high-speed shaft and increase the rotational speeds from about 30 to 60 rotations per minute (rpm) to about 1000 to 1800 rpm, the rotational speed required by most generators to produce electricity. The gear box is a costly (and heavy) part of the wind turbine and engineers are exploring "direct-drive" generators that operate at lower rotational speeds and don't need gear boxes.

7. Generator: Usually an off-the-shelf induction generator that produces 60-cycle AC electricity.

8. Controller: The controller starts up the machine at wind speeds of about 8 to 16 miles per hour (mph) and shuts off the machine at about 55 mph. Turbines do not operate at wind speeds above about 55 mph because they might be damaged by the high winds.

9. Anemometer: Measures the wind speed and transmits wind speed data to the controller.

10. Wind vane: Measures wind direction and communicates with the yaw drive to orient the turbine properly with respect to the wind.

11. Nacelle (nuh-SELL): The enclosure that houses the turbine's drive train, including the gearbox, the yaw mechanism, and the electric generator. The gearbox connects a low-speed shaft to a high-speed shaft. This mechanism can increase the speed of the shafts by a factor of as much as fifty to one, meaning that the high-speed shaft turns fifty times faster than the low-speed shaft.

12. High-speed shaft: Drives the generator.

13. Yaw drive: The yaw mechanism automatically senses the direction of the wind and rotates the rotor to keep it facing into the direction of the wind. Downwind turbines don't require a yaw drive, the wind blows the rotor downwind.

14.Yaw motor: Powers the yaw drive.

15.Tower: Towers are made from tubular steel, concrete, or steel lattice. Because wind speed increases with height, taller towers enable turbines to capture more energy and generate more electricity.

Wind Turbine Components copyright 2011 Digtheheat.com